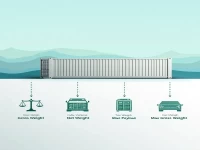

Logistics Industry Weighs Gross vs. Net Cargo Costs

This article explores the differences between gross weight and net weight in bulk transportation, highlighting that their relationship can vary based on packaging methods. For packaged bulk goods, there is a significant distinction between gross and net weight, whereas unwrapped bulk items have the same gross and net weight. Additionally, bulk cargo in maritime transport often consists of unpackaged goods, making the understanding of these concepts crucial for effective logistics management.